Before the Analysis¶

Sample Preparation¶

Filter samples before injection with a

SyringeandFilter.- Syringe filters can be found in the cupboard in the weighing room.

- Clean syringes can be found in sealed packets in the cupboard under the

HPLC.

Pre-Run¶

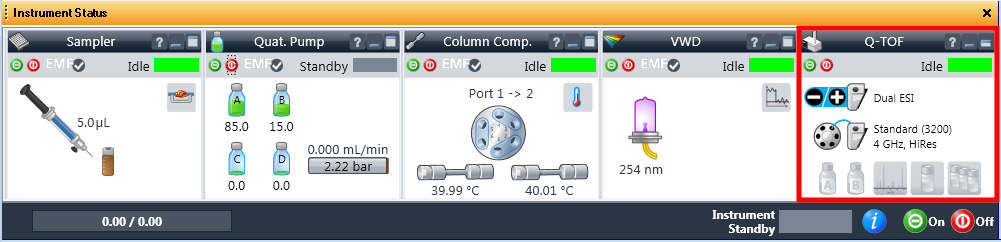

Check the indicator lights on the

Autosampler,Pump,Column,VWDandMSare notRed.Orange,Flashing OrangeorOffare OK.Check the valve near the

ESIon theMSis open (handle in line with pipe) and is connected toLon the nearby block (shown below)

Check that the pipe is connected to the port marked “L” to the left of this image, not to the port marked “H”

Check the levels of the bottles on the front of the

MS. Tap the bottles to disturb the liquid if the level is not obvious.Check the levels of the waste bottles in the following locations:

- Beneath the bench below the

Pump/Autosampler/Eluentstack - Beneath the bench below the

MSand behind theVacuum Pumps - Behind the

MS

- Beneath the bench below the

Check there is pressure in the

Collision Gas Bottlebehind theMS, and record the pressureCheck the 3

Exhaust Pipesare entering theExtractorfor theGraphite FurnaceReturn to the front of the instrument

Fetch some blue towel.

Open the

Ionisation Chamberof theMSand spray50% IPAaround (but not into) the metal surfaces of the inlet orifice.Spray the inside of the

Ionisation Chamberdoor and wipe with the blue towel.Close the

Ionisation Chamber.Open Mass Hunter Workstation Data Acquisition.

Check the pressures on the top right of the screen are within the following values:

Rough Vac < 4.4×10 0 Quad Vac 1×10 −5 - 4×10−5 TOC Vac 2×10 −7 - 4×10 −7 Check sufficient eluent is present in the eluent bottles being used for the run.

Check that the

Quat. Pumpis aware of the level of eluent in the bottles. To do this:Right click on the

Quat. Pumppanel of the Instrument Status window in MassHunter. <could use image here>Select Bottle Fillings from the menu.

Under Actual Volume, ensure the value reflects the volume of eluent actually present in the bottle.

The “Bottle Fillings” window

Click OK.

Repeat the above steps when Changing Eluent (see below)

Changing Eluent¶

To change an eluent, perform the following steps:

Right click on the

QTOFpanel of the Instrument Status window in MassHunter and select LC → Waste from the menu.

The Instrument Status window

In the Method Editor, under

Quat. Pump, set the Flow Rate to 0.000 mL/min and press Enter⏎Swap the the eluent bottles. Try to swap similar eluents; for example, replace Ammonium Formate with Ammonium Acetate.

- The Lids on the bottles do not need to be tight.

Open the valve behind the door on the front of the

Pump.Set the level of any solvents that weren’t changed to 0% and enable the eluents that were changed.

Set the Flow Rate to 1.000 mL/min and press Enter⏎

Check the pressure in the

Columndoes not rise above 0 Bar. If it does, check the valve at the front of thePumpis open.Set the Flow Rate to 5.000 mL/min and press Enter⏎

After 5 minutes, set the Flow Rate to 0.000 mL/min and press Enter⏎

Close the valve on the front of the

Pumpand close the door.

A method can be setup for flushing and equilibrating the column as part of the Worklist if desired